…By Providing Maintenance Consulting Services:

Many companies have an established maintenance programs in place utilizing tools such as Preventive Maintenance (PM) and Predictive Maintenance (PdM), but how is it working? As pressures to become more efficient and reduce costs increase, maintenance programs are often the first target for budget cuts. This is exactly the wrong response. Rather than trying to save short term money by cutting back on maintenance expenses, most companies should be taking a closer look at how their maintenance efforts are performing. This doesn’t necessarily mean that maintenance budgets should be increased either, but it does mean that you need to know what your maintenance dollars are doing for you.

- Do you know what your true maintenance costs are?

- What impact does maintenance have on your buildings and / or productivity?

- What does your work order backlog look like right now, and what should it look like?

- Which pieces of equipment are scheduled for PM and PdM?

- Are these activities being done? Are you sure?

- What is Reliability Centered Maintenance (RCM), and how can it help us?

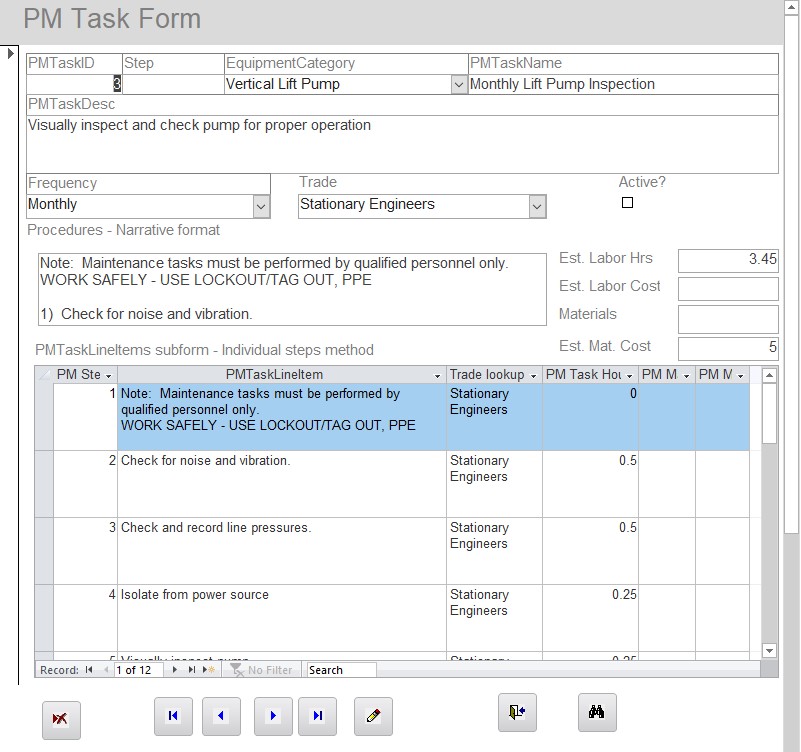

If your equipment falls into the category of standard building HVAC equipment, the development of an effective maintenance program is relatively straight forward. Between manufactures recommended services, standard practices, and first hand experience, preventive and predictive maintenance procedures can be developed and implemented without too much difficulty.

However, how will this get done? Who on your staff has the time, experience, and resources to dedicate to this effort? How will you focus on your day to day responsibilities while this process is being developed and implemented.

Michaud Engineering has the experience, knowledge, and resources to help you develop and deploy an effective pro-active maintenance program for your building equipment. Allow us to help you get this done right.

Developing and implementing an effective maintenance management program takes planning and experience. We can assist you in this process with expert analysis, the use of manufacturer’s recommendations, industry standards, and practices that will work for your facility. Here is just one step in the process:

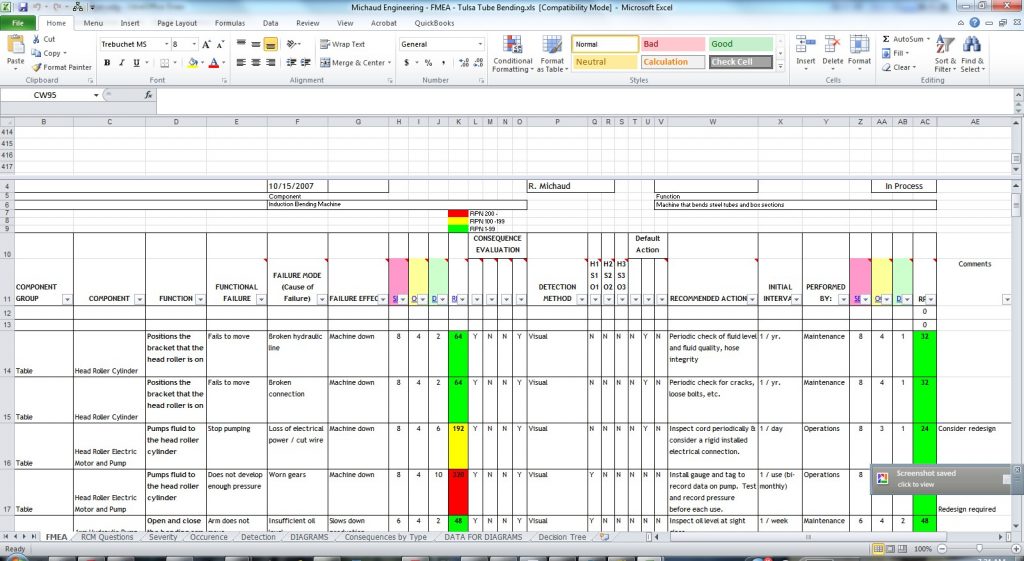

What if your equipment is less than standard or typical? Many manufacturers use very specialized equipment that has often been customized for the specific needs of the operation. How do you develop a maintenance program when there are to standard procedures and even the OEM recommendations no longer apply?

Michaud Engineering can help here too. Using the principles of Reliability Centered Maintenance (RCM) and associated tools, we can help you develop a customized set of maintenance procedures designed specifically for your machinery. These procedures factor in the safety, reliability and risk parameters that meet your particular needs.

If your equipment has been in “break-fix” mode because you are unsure how to develop maintenance procedures for it, improve your equipment reliability and up-time by having us help you develop the maintenance program that best suits your needs.

If you are a business owner, facilities manager or maintenance manager, you need to be able to confidently answer the above questions. If you can’t, there is a good chance you are not making the most of your maintenance expenditures.

Call Michaud Engineering – (888) 652-6777 – to discuss how you can better serve your organization by making better use of your maintenance money. We can help you review your existing maintenance program, set up a new Computerized Maintenance Management System (CMMS), and employ new methods to make your maintenance program more effective.